SCREW MACHINING PRODUCTION

At R/C Machining Company, our equipment assets include an arsenal of fast and versatile multi-spindle screw machines. The benefit of these machines is that we can set them up to use multiple tools to cut multiple pieces of material simultaneously. We carry out a variety of operations, such as turning, boring holes, threading, drilling, and tapping at fast cycle times, which enables us to generate a high volume of parts quickly and cost-effectively.

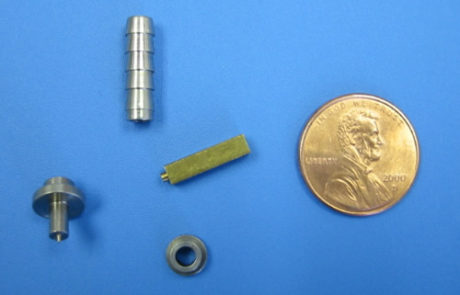

With our automatic multi-spindle screw machines, we produce precision parts measuring from 1/8″ to 2-5/8″ in diameter. Materials we commonly work with include alloy steel, aluminum, and stainless steel along with rigid plastics such as nylon, acetal, reinforced plastics, and others. Our screw machining expertise enables us to uphold tolerances as close as ± 0.001″ consistently.

We operate a lineup of twelve multi-spindle screw machines with various capacities as well as two single-spindle machines. Automation features allow these machines to run continuously with very little operator intervention. Both in-process and final inspection ensures products comply with all quality criteria. To support our screw machining services, we offer an extensive selection of value-added services. Along with heat treating and a variety of finish options, we offer product assembly and custom packaging.

Whether it is a small order of custom fittings or a high volume of fasteners, hardware, or automotive parts, we react quickly and get the job done with lightning-fast turnaround time. We provide a dedicated customer support person who is always accessible and maintains individual responsibility for an order from start to finish. To learn more about our multi-spindle screw machining operations or to make an inquiry, contact us directly.